The rapid advancement of technology is reshaping various industries, and the realm of electronics is no exception. Central to this evolution is the printed circuit board, commonly referred to as the PCB board, which serves as the backbone of modern electronic devices. As we approach 2025, innovations within PCB board technology are poised to revolutionize the way we design and manufacture electronic components, enhancing performance, efficiency, and reliability. This article delves into the top 10 innovations in PCB board technology that every electronics professional should be aware of.

In the coming years, we anticipate breakthroughs that will streamline production processes, reduce costs, and improve circuit density while maintaining the essential functionality of PCB boards. We will explore innovations such as multilayer boards, flexible circuits, and advanced materials that promise to push the boundaries of what is possible in electronic design. Understanding these trends not only prepares designers for upcoming challenges but also highlights opportunities for integrating state-of-the-art technology into their projects.

Join us as we uncover the pivotal advancements that will shape the future of PCB board technology and its impact on our increasingly connected world.

The landscape of PCB (Printed Circuit Board) technology is experiencing a transformative shift thanks to emerging materials that significantly enhance durability and performance. Advanced substrates, such as high-temperature laminates and flexible materials, are being developed to withstand extreme conditions while maintaining electrical integrity. Innovations like Ceramic-filled Polyimide and Liquid Crystal Polymer are showing exceptional promise in delivering lightweight solutions that resist thermal expansion and improve signal integrity.

Tips for selecting PCB materials: Consider your project's specific environmental conditions and performance requirements. High-frequency applications may benefit from low-loss materials, while high-temperature processes require robust thermal stability. Always consult with material suppliers to stay updated on the latest advancements in PCB technology that could benefit your design.

In addition, conducting thorough testing during the prototyping phase can help identify potential issues related to material choice early on, saving time and resources in the long run. Embracing these cutting-edge materials not only ensures a competitive edge but also aligns with the industry's increasing demand for sustainability and reliability in electronic components.

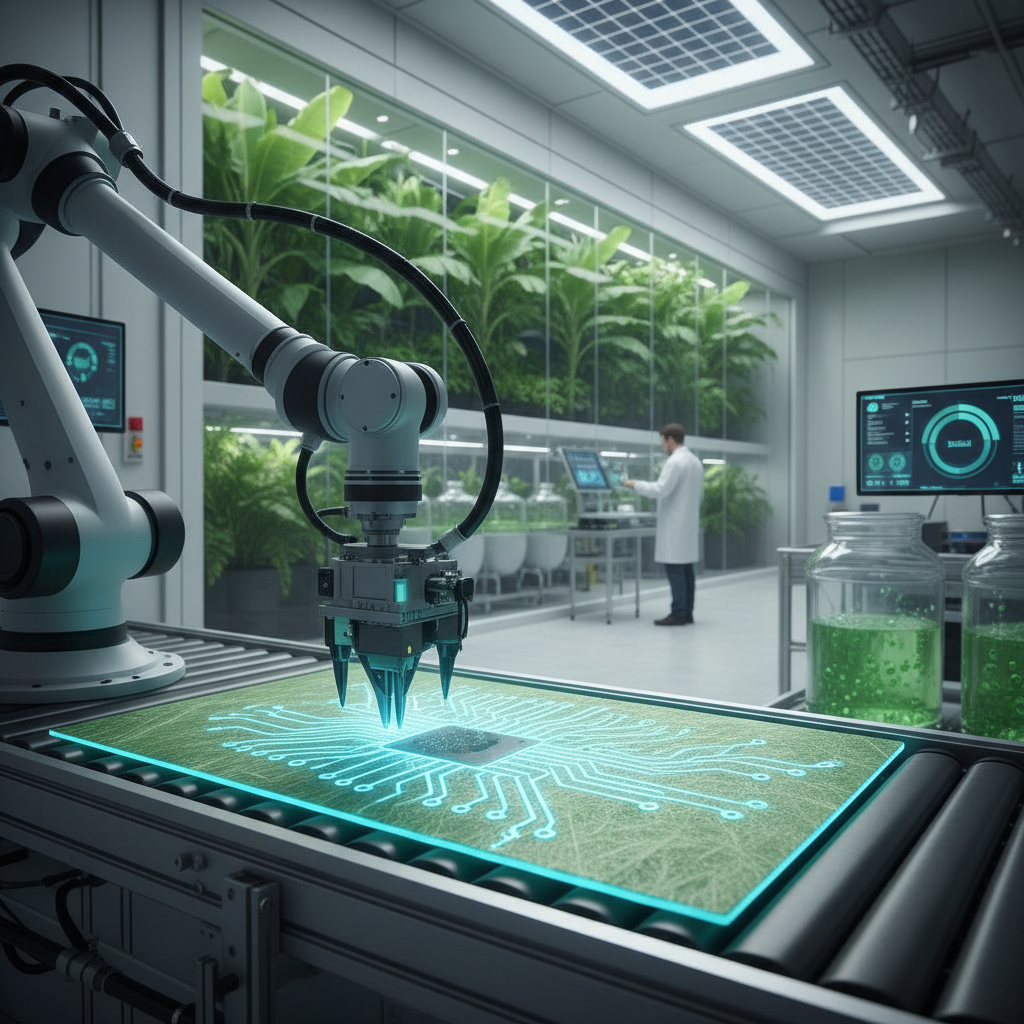

Recent advancements in advanced manufacturing techniques are revolutionizing the production of printed circuit boards (PCBs), leading to higher precision and efficiency. According to the IPC Global Market Statistics Report, the PCB industry is projected to reach $80 billion by 2025, fueled by innovations in technology and manufacturing methods. Techniques such as additive manufacturing and laser drilling are gaining traction, enabling the production of complex designs that were previously infeasible. These methods enhance the precision of layer stacking and minimize inaccuracies, which are critical for high-density interconnect (HDI) applications.

The shift towards automation in PCB manufacturing is also noteworthy. As highlighted in a 2023 report by Research and Markets, the implementation of robotics and AI-driven processes is expected to increase productivity by up to 30%. This not only reduces human error but also allows for real-time monitoring and adjustments, ensuring consistency in quality. Furthermore, technologies like smart manufacturing and the Internet of Things (IoT) are enhancing data analytics capabilities, which help in predictive maintenance and operational efficiency. As these innovations continue to develop, they play a crucial role in meeting the evolving demands of industries such as automotive, aerospace, and consumer electronics.

This chart illustrates the advancements in PCB board technology based on their expected impact and implementation in 2025. The innovations are ranked by their significance and potential to enhance manufacturing precision.

The integration of smart technology into PCB design is revolutionizing the electronics industry, particularly as we advance towards 2025. The global PCB design software market is projected to grow from $682.28 million in 2026 to $1.10468 billion by 2035, demonstrating a stable compound annual growth rate (CAGR) of 5.5%. This growth is driven by the increasing demand for sophisticated designs that incorporate functionalities like multi-protocol support and enhanced wireless communication. As IoT devices continue to proliferate, the role of multi-protocol System-on-Chips (SoCs) in managing various wireless communications has never been more critical.

Additionally, developments in artificial intelligence are set to significantly enhance PCB design efficiency. Siemens has integrated new AI features into its Electronic Design Automation (EDA) suite, which aims to boost productivity and accelerate innovation, thus shortening time-to-market. With the global EDA industry expected to generate $4.9 billion in revenue, reflecting an 11% year-on-year growth in the fourth quarter of 2024, the integration of smart technologies in PCB design is not merely a trend; it is becoming a necessity for companies aiming to stay competitive in an evolving market.

The demand for sustainable practices in printed circuit board (PCB) manufacturing is becoming increasingly crucial as the electronics industry faces significant environmental challenges. With a projected market size of approximately $80 billion by 2025, driven by innovations in sustainability and eco-friendly materials, it's essential for businesses to adapt to these trends. For instance, the use of advanced materials like g-C3N4 reinforced banana natural fiber showcases the shift towards more sustainable PCB substrates, aiming to reduce waste and reliance on traditional materials.

As companies implement these sustainable innovations, an increasing number are focusing on circular economy principles, such as designing PCBs for easier recycling and utilizing eco-friendly production processes. According to industry reports, initiatives aimed at sustainable PCB manufacturing often emphasize comprehensive regulatory compliance while pushing for greater environmental responsibility. These trends not only enhance corporate social responsibility but also meet rising consumer demands for greener products.

Tips:

1. Stay informed about emerging sustainable materials that can enhance your product offerings and appeal to environmentally conscious consumers.

2. Consider partnering with startups focused on eco-innovations to leverage fresh ideas and advanced technologies in your PCB production processes.

The reliability and quality of printed circuit boards (PCBs) are paramount in today’s electronics market, where performance standards are continually rising. Next-generation testing methods have emerged to meet these demands, utilizing advanced technologies such as automated optical inspection (AOI) and X-ray imaging. According to a report by IPC, over 60% of manufacturers are adopting such innovative testing solutions to minimize defects during the production phase. These tools not only enhance the ability to detect issues early but also reduce the time taken for manual inspections, ultimately resulting in higher throughput and efficiency in PCB manufacturing processes.

Moreover, the integration of artificial intelligence (AI) into testing methodologies is a game-changer. AI algorithms can analyze data from previous tests to predict potential failures, flagging components that may not withstand the rigors of operation. A recent study highlighted that implementing AI-driven testing methods can increase fault detection rates by up to 30%, thereby significantly improving product reliability. As the demand for high-performance electronics grows, employing these next-generation testing techniques will be crucial for manufacturers aiming to ensure the quality and reliability of their PCB technologies in 2025 and beyond.